Robot in the Bloodstream:

Force of Blood Incident on Robot:

Fblood = ⍴QΔv

Force Exerted on Robot

= 1.247 * 10-5 N (W/ 60 degree Conicular Head)

Known Variables:

Reynolds Number ~ 167 -laminar flow

Average Velocity ~ 150 – 350 mm/s -In larger arteries where surgery takes place

Density of blood, ⍴ = 1043 – 1060 Kg/m^3

Viscosity of Water ~ 0.001002 kg/ms

Viscosity of Blood ~ 0.00401 kg/ms

Drag Force of Blood on Robot:

Cf = 1.33 / (Re1/5)

Cf = 0.478

FD = ½*Cf*⍴*V2*As

Drag Force of Blood on Robot

= 5.61 * 10-6 N

Known Variables:

Flow Rate of Blood, V ~ 0.25 m/s

Coefficient of Friction = Cf

Density of Blood, ⍴ = 1052 kg/m3

Velocity of Blood, V = 0.0066 m/s

Cross-sectional Area, As = 0.000512 m2

Pressure on Arterial Wall/ Friction:

FNormal = Fexterted / μ

Fnormal = mass * gravity

Known Variables:

Frictional Coefficient, μ ~ 0.3

Mass of Robot = 0.01731 kg -Per link of robot without actuator weight

Pressure felt by Arterial Wall ~ 16,000 Pa

Other Analyses:

Equivalent Reynolds Number of Fluid at 10x Scale:

Reynolds Number Equation:

Re = ⍴VD/μ

Required Velocity of Simulator:

V = 0.008 m/s

Known Variables:

Water Density = 1,000 kg/m3

Average Water Velocity = ? m/s

Arterial Simulator Diameter = 0.025m

Dynamic Viscosity of water = 8.9 * 10-4 kg/ms

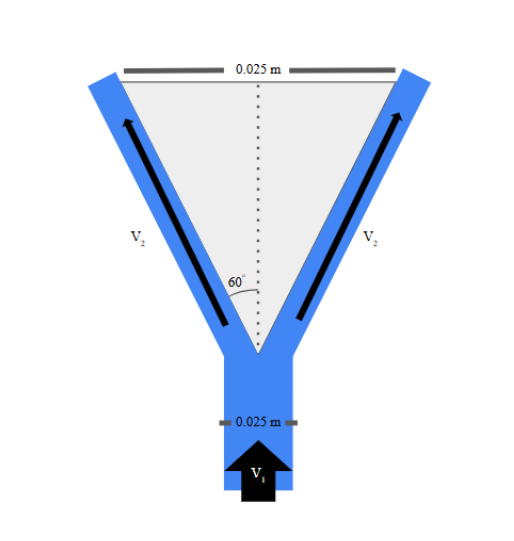

Force Incident on Robot Head as a Result of Simulated Flow:

Governing Equation:

F = ⍴A1(-V1)2+⍴A2(V2)2 + ⍴A2(-V2)2

F = 3.527 * 10-4 N

Known Variables:

Flow Velocity, V1 = 0.008 m/s

V2 = 0.00693 m/s

Cross Section of Flow, A1 = 4.909*10-4 m2

Cross Section of Deflections, A2 = 0.004 m2

Density of Water, ⍴ = 1,000 kg/m3

Structure Material Analysis:

Governing Equations

εtot = εp * 1 / (1 + ψ)

ψ = Ests / Eptp = 225

εtot = 1.26*10-5

εtot = M / ZEt

Z = ⅙ Width * Thickness2 =8.33 *10-7

M = 4.73*10-4 N

Known Variables:

Structure material-

Thickness, ts = 20mm

Width = 0.0125 m

Length = 0.04m -Determined within Design

Young’s Modulus, Et ~0.045 Gpa

M = Applied Force

Magnetic Holding Force:

F = B2 * A / (2 * μ0)

F = (1.25)2 * ( ) / (2 * 4π * 10-7)

Known Variables:

Surface Area of Magnet = X m2

Flux Density, B = 1.2 Kg/Cs

Permeability, μ0 = 4π x 10-7 kg*m2/s2(C/s)2

Insight Gained

-robot must allow blood flow to continue

-have head of robot be a Conical Deflector

-if tether is present, addition friction will need to be considered

Potential Future Calculations

-Cycle Time

-Average distance needed to be traveled/ ideal time of surgery

-Friction force on exterior of robot link